Short Intro About Wellhead Control Panel.

Top Channel Partner

UniversalTech Automation partnered with top Wellhead Control Panel Manufacturers in UAE & Europe for onsite installation, commissioning, startup and maintenance of equipment’s.

We Design,

manufacture, supply and install various types of wellhead control panels (WHCP) for the control, monitoring and safety of oil and gas production wells. All our systems are built in line with customer specifications and international standards.

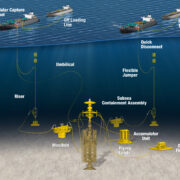

Wellhead and Christmas tree

Products are used to monitor well pressure, adjust oil/gas well flow and prevent the release of hazardous liquid and gas from entering into air or water during drilling and oil & gas production.

Acidizing, Fracturing

They can be applicable for acidizing, fracturing, water flooding and testing as well. We are dedicated to providing safe and reliable wellhead panel and equipment for global customers. Wellhead control panel are also known as shutdown panels (SDP), Emergency Shutdown Systems (ESD) and Hydraulic Safety Shutdown System(HSSS).

Types of Wellhead Control Panels

• Single Wellhead Control panels

• Modular Multi-Well Wellhead Control Panels

• Hydraulic Power Units

• Solar Powered Well Head Control Panels

• PLC Integrated Wellhead Control Panels

Design considerations

• Application: onshore (single well) / offshore (multi well)

• Installation: permanent/temporary (well test)

• Power available: solar, gas, air, electricity

• Hazardous area classification: zone 0, zone 1, zone 2 / zone unclassified

• Level of complexity: conventional, hybrid, state of the art

• Remote control requirements

• Emergency shut down (ESD) and process shut down requirements

Achievements

- CSPs designed and installed at Anyala West – OML83 (ANDP1) and Madu –OML85 (MADP1) locations, where the water depth is between 30 m and 50 m, with a 15 years design life.

- The Anyala west platform (ANDP1) WHCP had 5 Production (current), plus 7 future slots, and MADU (MADP1) platform had 6 production and 6 future slots. Therefore only the WHCP drawer modules were required at the control panel. Bulkhead connection sizing was included in the relevant section of the specification. A separate Wellhead Control Panel was provided for the ANDP1 platform and the MADP1 platforms.

- Generation of two hydraulic pressures 207 Barg (LP) (HOLD 1) and 345 Barg (HP) (HOLD 1) headers).

- SWEPT volume 0.06LTRS

Short